Pensky-Martens Closed Cup Test Procedure

Summary

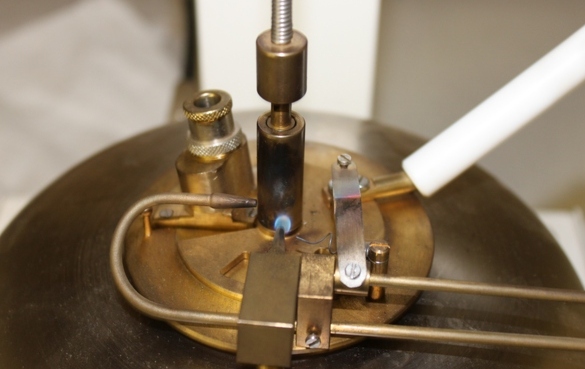

The Pensky-Martens Closed Cup Tester can be used to determine the flashpoint of a petroleum product in the temperature range 40-360°C. The procedure used to determine the flashpoint is dependent on the petroleum product. Procedure A applies to distillate fuels such as diesel or kerosene, while procedure B is applicable to residual fuel oils, petroleum liquids that form a surface film under test conditions and used lubricating oils amongst others. The sample is contained in a brass test cup which is placed inside the apparatus and fitted with a testcover. The sample contained in the test cup is heated and stirred simultaneously. An external ignition source is periodically directed into the test cup (this momentarily interrupts the stirring). This is done until a flash is observed (meaning the sample has reached its flashpoint).

Apparatus Preparation

• The apparatus should be supported on a level surface such as a table.

• The test should under all circumstances be performed in a fume hood

• Thoroughly clean the test cup using acetone and ensure it is completely dry after being cleaned (acetone is flammable!).

• Ensure that a properly calibrated thermometer is inserted into the apparatus.

• Ensure that the gas cylinder is properly connected to the flashpoint apparatus.

Test Procedures

Procedure A

1. Fill the test cup with the sample (up to the filling mark ) and ensure that the temperature of the sample is at least 18°C below the expected flashpoint of the substance.

2. Open the gas and light the test flame using an external ignition source. Adjust the flame to a diameter of 3.2 to 4.8mm using the dial on the front panel of the instrument.

3. Apply the heat to such an extent that the temperature of the sample increases by 5-6°C/minute.

4. Switch on the turning device and ensure that it turns at a rate of 90 to 120 rpm.

5. Application of Ignition Source

5.1. If the expected flashpoint temperature of the sample is 110°C or lower, the ignition source must be applied when the sample temperature is 23+/-5° C below the expected flash point and thereafter each time the temperature has increased by 1°C. Apply the ignition source by discontinuing the stirring of the sample and lowering the ignition source into the vapour space of the test cup (using the white lever on the test cover).

5.2. In the event that the expected flashpoint temperature of the sample is higher than 110°C, apply the ignition source as described in 5.1 at each temperature increase of 2°C.

5.3. When testing a sample to determine only whether volatile material contamination is present, the temperature limits proposed in 5.1 and 5.2 need not be adhered to.

5.4. In the event that the expected flashpoint temperature of the sample is not known, ensure that the temperature of the sample is 15+/-5°C. If the sample is very viscous at this temperature, heat it to a starting temperature as described in 5.1 and 5.2. Apply the ignition source (using the procedure described previously) beginning at least 5°C higher than the starting temperature.

5.5. Record the flashpoint temperature as observed on the thermometer. This is done when a distinct flash within the test cup is observed on application of the ignition source.

6. Allow the apparatus to cool down to a safe temperature (less than 55°C) and then remove the cover and test cup and clean as recommended in apparatus preparation.

Procedure B

1. Fill the test cup with the sample (up to the filling mark ) and ensure that the temperature of the sample is at least 18°C below the expected flashpoint of the substance.

2. Open the gas and light the test flame using an external ignition source. Adjust the flame to a diameter of 3.2 to 4.8mm using the dial on the front panel of the instrument.

3. Switch on the turning device and ensure that it turns at a rate of 250+/-10rpm.

4. Apply the heat to such an extent that the temperature of the sample increases by 1-1.6°C/minute.

5. Proceed as indicated in section 5 and 6, procedure A.