HFRR test procedure

From Chemical Engineering @ UP wiki

Contents

Filtration

- Beforehand, all equipment that will come in contact with the diesel sample must be rinsed thoroughly with heptane and then air dried

- Place two 0.8 micron meter Nylon Membrane Filters in the oven at 110 °C for 10 minutes to eliminate unwanted moisture

- After the 10 minutes weigh them individually and write it down

- Place both filters on the mesh with the heaviest one on top, as to distinguish between them

- Fix the long tube to the piece with the mesh with the two bolts

- Check to see that the filters cover the mesh properly to prevent leaks

- Fix the tube in both clamps of the stand

- Measure 500 ml of sample fuel and pour into tube

- Connect the vacuum pump to the (glass bottle?) and switch the pump on to start filtering

- When finished, switch the pump off and disconnect it from the (glass bottle?)

- Pour filtered fuel in storage container

- Rinse tube with heptane while still assembled and vacuum suck the heptane into another (glass bottle?)

- Take the long tube and the lower piece apart

- Place both filters in the oven, still with the heaviest one on top, at 110 °C for 15 minutes to evaporate heptane

- Weigh filters again and write it down

High Frequency Reciprocating Rig

Preparation of Apparatus

- After the completion of a test ALWAYS leave the balls, plates and utensils in the toluene bath.

- Check under microscope that upper ball specimen is turned so that the next test will be done on a surface with no wear/scratch marks.

- Switch on the toluene ultrasonic bath and set the timer to 10 minutes.

- Place the top specimen, lower specimen, screws and all the hardware and utensils in the ultrasonic toluene bath, and leave for 10 minutes.

- Now place everything in the acetone ultrasonic bath and switch it on for another 10 minutes.

- When you transfer the specimens NEVER PHYSICALLY TOUCH THE BALL OR THE DISK, AS THE OIL ON YOUR FINGERS WILL FORM A BOUNDARY LAYER. Use a clean tweezer (left in toluene) if you need to handle the ball or the disk.

- Remove the specimens from the ultrasonic acetone bath after 10 minutes and blow dry it.

Calibration and Correction

See ISO12156 Section 7.2.

Test Procedure

- Only use already filtered diesel samples to test on the HFRR.

- Greatest care should be taken to adhere strictly to cleanliness requirements. Always use clean tweezers when handling the specimens and the hardware and be sure not to scratch them.

- Turn lower disc specimen to get a clean surface for new test using a tweezer.

- Fasten lower specimen to HFRR machine, with the nipple on the right hand side, with the two small bolts.

- Fasten upper specimen to oscillating arm with the remaining one small bolt. Be sure that the holder is horizontal before fully securing the unit.

- BE CAREFUL NOT TO OVER-TIGHTEN THE SCREWS, THEY ARE STRIPPED EASILY.

- Put 2ml of diesel sample in the lower specimen reservoir using the pipette (flush the pipette with acetone twice and dry it before contact with diesel). BE SURE TO SHAKE THE SAMPLE BEFORE USING IT FOR TESTING.

- Attach the sling and the 200g weight to the extended arms of the upper specimen. Ensure that the suspension string hangs freely.

- Put silver thermometer in hole next to the nipple (not in the sample itself, but in the lower block).

- Open the HFRR program on the computer.

- Click on 'New Test'.

- Ensure that the ISO12156 standard procedure is selected.

- We are using an unknown fuel sample.

- Name the file in which the program will save the data from the test.

- Click on 'Start'.

- The test will only start when the temperature has stabilized at 60degC.

- After the test have finished (75min), remove the top specimen from the configuration.

- Without removing the ball from the test ball holder, rinse the holder several times using toluene and then several times using acetone.

- Ultrasonically clean the top specimen for 30s using toluene.

- Ultrasonically clean the top specimen for 30s using acetone.

- Allow the top specimen to air dry.

Measuring the wear scar

- Place the upper ball specimen under the microscope.

- Use the IC10 magnification and focus the image.

- Use the ruler in the right eye lens to measure the horizontal wear scar diameter (x) and the vertical wear scar diameter (y).

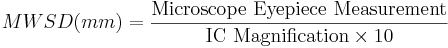

- The following formula is used to calculate the MWSD (measured wear scar diameter):

- Insert these values into the HFRR program.

- This is done by clicking on the "Wear Scar" box.

- The program asks you whether you want to insert the values manually. Say Yes.

- Enter both the horizontal (x) and vertical (y) wear scar diameters.

- Under the comments section give the wear scar a complementary rating according to Olah et al. e.g. "Complementary Rating = 5". The complementary rating method by Olah et al. can be found here

- Also tell the program to calculate the WS1.4. This is the wear scar corrected to a water vapour pressure of 1.4kPa (this is to bring the effect of humidity into account).

Exporting the data to Excel

- All the data has now been captured.

- Click on "Export Test".

- Save your .txt-file in the "Shortcut to Results" folder on the desktop. All HFRR results are stored here. Give it the same name as the one used in the beginning of the test e.g. "Catpoly Diesel U33_1.txt".

- A template Excel data capturing file exists, so just open any one of the previous tests and copy the contents of the new .txt file into the Excel sheet. New graphs are drawn for the new sample.

- Delete the old photo.

- Rename the file e.g. "HFRR Catpoly Diesel U33_1 (17Feb2010).xls"

Taking a photo of the wear scar

- Connect the camera to the top of the microscope. Let someone show you how to do this.

- Focus the microscope on the wear scar on the ball and take a picture with the digital camera.

- ENSURE THAT THE PHOTO IS IN FOCUS.

- Sometimes when the wear scars a really big the wear scar will not fit the picture if the IC10 magnification is used. If this is the case use the IC5 magnification for the taking of the photo.

- If the microscope is switched on but the light does not seem to come through, lower the the voltage on the voltage control box of the microscope.

- Take between three and five photos of the wear scar.

- Select the best photo on the computer and delete the rest of them to save space on the data card.

- Copy this picture into the Excel spreadsheet discussed earlier and save the sheet.

PLACE ALL THE SPECIMENS AND EQUIPMENT IN THE TOLUENE BATH.