Tribology

Contents

[hide]What Exactly Is Tribology?

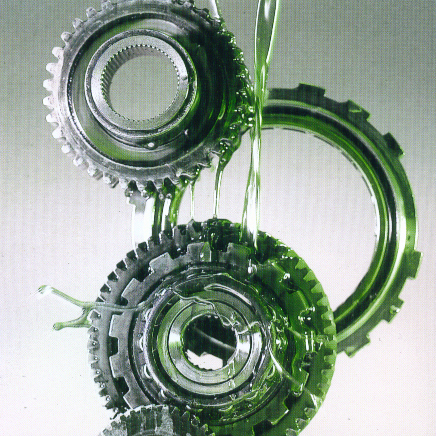

In essence, tribology is the science and engineering of interacting surfaces in relative motion. This includes research and application of friction, wear and lubrication. (Mang, Bobzin & Bartels, 2011: 1)

Theoretical Background

Research in the Tribology laboratory at the University of Pretoria centres mainly around the study of lubricants and their lubricity, particularly that of diesel. Lubricants applied to mechanical systems generally form a film or separating layer between two interacting surfaces which reduces wear rates and the coefficient of friction. The coefficient of friction is defined as the ratio of the frictional force to the normal force of the load applied to the surface concerned (Mang et al, 2011: 26). Lubricity can be seen as a measure of how effective a lubricant a particular fluid is. Lubricity cannot be measured directly and is therefore determined by the amount of wear on an interacting surface. Wear is defined as the progressive loss of material from the surface of a solid object due to mechanical causes-that is, the contact with and frictional motion against a solid, liquid or gaseous counter body (Mang et al, 2011: 37). Various types of wear include adhesion, abrasion, corrosion, tribochemical reactions (usually oxidation) and surface fatigue (Mang et al, 2011: 38). Ultimately the more wear experienced by two interacting surfaces the worse the lubricity of the lubricant applied to the surfaces.

The Lubricity of a fuel depends on factors such as (www.biodiesel.org, 26 November 2011) the composition of the crude oil source from which the fuel was produced (sulphur found in the original source has good lubricity properties but much of it is removed due to environmental concerns), the refining processes used to produce the fuel and the handling of the fuel during distribution. The addition of lubricity enhancing additives (such as antioxidants, viscosity modifiers and many others) also has an affect on the lubricity.

Mang, T, Bobzin, K and Bartels, T (2011) Industrial Tribology: Tribosystems, Friction, Wear and Surface Engineering, Lubrication, WILEY-VCH & Co. Weinheim, Germany

www.biodiesel.org/pdf_files/fuelfactsheets/Lubricity.PDF [2011, November 26]

Tribology Laboratory - University of Pretoria

The tribology group is headed by Professor Philip de Vaal and was started in 1987 with support from ESKOM, Anglo-American and ISCOR. The activities in the lab focus on lubricant performance evaluation, which includes analysis of greases, oils and diesels. More recent industrial problems with diesel quality in South Africa motivated research in the field of diesel lubricity and biodiesel, sponsored by Sasol.

The Tribology Lab not only functions as a academic research lab, but also as an evaluation lab for industry. Several companies use the Tribology Lab for failure analysis and quality control.

The first section gives information regarding the equipment used in the Tribology Lab. The user manuals, test procedures and ASTM/ISO/DIN/SABS standards for each piece of equipment is included in the respective pages. Documentation of past and present projects can also be found there.

The second section includes all the work and some of the literature regarding hip tribology, and the third section has all the past |test results done for partners in industry. A password is required to access this page.

Section five gives access to all the ASTM/ISO/DIN/CEC/SABS standards and procedures that are not included in the equipment section. You will also need a password to access this page.

The last section contains all the project files and documents of students who worked on the diesel lubricity and biodiesel project.

Click here to gain access to files on the computers in the Tribology Lab (A password is required.)

You will find this page most useful when starting out with a new project or when you just have a problem in the lab. The aim of this site is also to log everything that happens in the lab to help create continuity between students responsible for the well-being of the lab.

Equipment

The following lubrication bench tests are available in the Tribology Lab. A hard copy of the documentation of each test rig is also available in a red file of the same number as the rig.

Documentation for projects done on the FZG machine can be found here

Documentation for projects done on the SRV machine can be found here

T03 BICERI Universal Wear-testing Machine

Documentation for the projects done on the BICERI UWM can be found here

T04 High Frequency Reciprocating Rig (HFRR)

Documentation, standards and test procedures regarding the HFRR can be found in this section.

T05 Mettler Toledo XP2003S Comparator Balance

Documentation and areas of application can be found in this section.

T06 US Steel Mobility Test Rig

Documentation and test method can be found in this section.

T07 Pensky-Martens Closed Cup Tester

This piece of equipment is used to determine the flashpoint of petroleum products. Documentation and test method can be found in this section.

Documentation and test method can be found in this section.

Documentation and test method can be found in this section.

T10 NDI 440 Automatic Distillation Machine

This piece of equipment is used to determine the boiling point characteristics of petroleum products. Documentation and test method can be found in this section.

T11 Optimol SRV 4 Machine (New Machine)

Documentation for projects done on the SRV 4 machine can be found here

Documentation, test methods and projects on this can be found in this section.

Documentation, test methods and projects on this can be found in this section.

T15 Carl Zeiss Axio Scope A1 Microscope

Documentation, test methods and projects on this can be found in this section.

Documentation, test methods and projects on this can be found in this section.

Documentation, test methods and projects on this can be found in this section.

T18 Karl Fischer 787 KF Tritrino

Documentation, test methods and projects on this can be found in this section.

Documentation, test methods and projects on this can be found in this section.

General Laboratory Safety and Information

This section includes relevant information needed by those who work in the Tribology labaratory as well as general laboratory procedures and safety measures. Click on General Laboratory Safety and Information to access this page.

Hip Tribology

This section includes all the projects done on hip tribology. Click on hip tribology to access the page.

Test Results

This section contains all the test results that has been obtained for clients in industry. A password is required for access. Click on Test Results.

Standards and Procedures

All the local and international standards and specifications applicable to fuels and the operation of equipment in the Tribology Lab are available here. A password is required to access the information.

ASTM Standards and Specifications (Click here)

EN Standards and Specifications (Click here)

ISO Standards and Specifications (Click here)

SABS Standards and Specifications (Click here)

Diesel and Biodiesel lubricity

This section contains all the work done at the University of Pretoria, regarding diesel and biodiesel lubricity. Click on Diesel and Biodiesel Lubricity to access the page.

Tribology Library

This section contains some of the most crucial tribology literature. Much of this literature is not available at the Merensky Library and was interlended by previous students. A file with some of the important literature is available in hard copy. A password is required to access the literature.

Textbooks

Stachowiak and Batchelor (2005) Engineering Tribology

Textbook

Ludema (1996) Friction, Wear and Lubricity A textbook in Tribology

Textbook

Categories

Diesel Injector and Pump Modelling

Diesel Lubricity Test Methods and Chemistry Effects

Experimental Analysis of Boundary Films