Bioreactor

Description

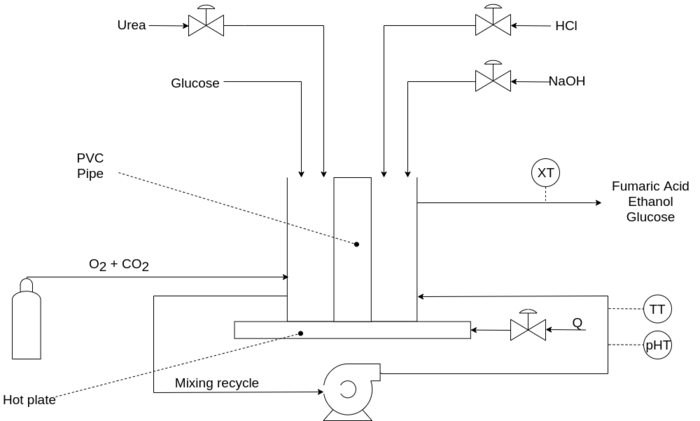

Fumaric acid and ethanol are produced through the aerobic fermentation of glucose by Rhizopus oryzae. Ethanol is an unwanted by-product and its concentration is reduced by sparging with carbon dioxide. There are two phases in the process: a growth phase and production phase. During the growth phase, the fungus is grown on a PVC pipe within the cylindrical fermentation vessel with high concentrations of urea in a batch process. Thereafter, in the production phase, the vessel is rinsed out and continuous fermentation begins with lower concentrations of urea.

Mixing in the vessel is caused by the continuous recycling of the reactor fluid from the base to the head of the reactor and as such the system is modelled as a CSTR. The direction of the recycle switches periodically to prevent the build-up of fungus and subsequent clogging of the pump. Volume is kept constant through the use of an overflow. The overflow's fumaric acid, glucose and ethanol concentrations is measured.

Previous work

On the bio side much work has been done by Andre Naude who did his PhD on the reactor in 2018. The three published papers relating to his work can be found here, here, and here. His full PhD thesis can be found