Difference between revisions of "T03 BICERI Universal Wear-testing Machine"

(→2010 (Current)) |

(→2011 (Current)) |

||

| Line 16: | Line 16: | ||

=== 2011 (Current) === | === 2011 (Current) === | ||

| + | "Howard Benade: Development of automation mechanisms for the Biceri Universal Wear-testing Machine" | ||

== Documentation == | == Documentation == | ||

Revision as of 11:32, 29 November 2011

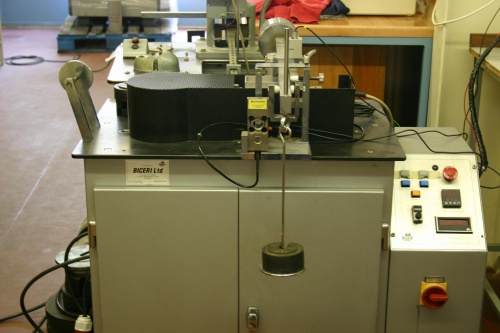

Dr Terry Eyre from Brunel University in the UK developed a multi-functional wear-testing machine and the British Internal Combustion Engine Research Institute (BICERI) distributed it. It was called the “BICERI Universal Wear-testing Machine”. The machine is multi-functional in that it incorporates three different wear contact regimes, mentioned below:

- Pin-on-reciprocating plate module;

- Rotating pin-on-disk module; and

- Block-on-ring module.

Each of these wear contact regimes could be studied by a configuration of the hardware provided.

More than 10 years ago Sasol purchased a Universal Wear Machine from BICERI, wanting to utilize its diversity. Unfortunately this was right around the time that BICERI went bankrupt. Sasol received the machine, but it could never be fully commissioned due to faulty software. The machine was donated to the University of Pretoria a few years ago and was commissioned in 2009 as a CML project.

Contents

Current/Previous projects

2009

Gerhard Marais, Commissioning of the BICERI Universal Wear Machine

Report | Project files

2011 (Current)

"Howard Benade: Development of automation mechanisms for the Biceri Universal Wear-testing Machine"

Documentation

Wiring diagrams

The machine's wiring diagram is included in the BICERI UWM-file. It was drawn by hand due to the unavailability of wiring diagram from BICERI. The file contains the wiring diagram of the junction box. .VSD (Visio) | .PDF

The BICERI Machine as test metal cutting apparatus

Howard Benade will fill this gap.