Difference between revisions of "T02 Optimol SRV Machine"

| Line 19: | Line 19: | ||

=== Wiring diagrams === | === Wiring diagrams === | ||

A scan of the SRV wiring diagram can be found [ftp://anonymous@ragnarok/publicftp/lab/Tribology/SRV/SRV_Bedradingsdiagram.pdf here] | A scan of the SRV wiring diagram can be found [ftp://anonymous@ragnarok/publicftp/lab/Tribology/SRV/SRV_Bedradingsdiagram.pdf here] | ||

| + | |||

| + | == Test Procedure == | ||

Revision as of 12:13, 8 February 2010

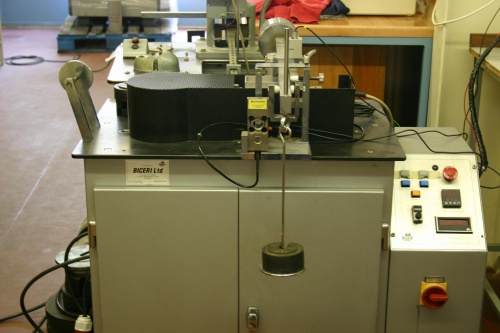

The SRV apparatus (German acronym for oscillation, friction and wear) is a 1986 model that was donated to the University of Pretoria in 1987. The machine traditionally tests the lubricating properties of oils and greases, but at the University of Pretoria it is used to test diesel lubricity together with the HFRR. The machine measures the load carrying capacity (LCC) of a certain fluid by measuring when film break though occurs. The machine utilizes a ball-on-disk configuration and can be operated in one of two conditions:

- A constant load test (like the HFRR); and

- An increasing load test where the load increases @ 50N/min.

There is no ASTM or ISO standard for testing diesel fuel with the SRV but the "in-house" test developed for testing diesel utilizes conditions that are closer to that of modern engines, when compared to the HFRR.

Contents

Current/Previous projects

2007

Petri Labuschagne, Upgrade of the SRV test equipment

Report | Project files

Documentation

User Manuals

The SRV User Manual can be found here

Wiring diagrams

A scan of the SRV wiring diagram can be found here