Difference between revisions of "Big distillation column"

(→Operator interface) |

(→Operator interface) |

||

| Line 10: | Line 10: | ||

==Operator interface== | ==Operator interface== | ||

| − | [[Image:gui.png|1050px|Image: | + | [[Image:gui.png|1050px|Image: 1000 pixels]] |

==Contact persons== | ==Contact persons== | ||

Revision as of 13:35, 17 November 2018

Contents

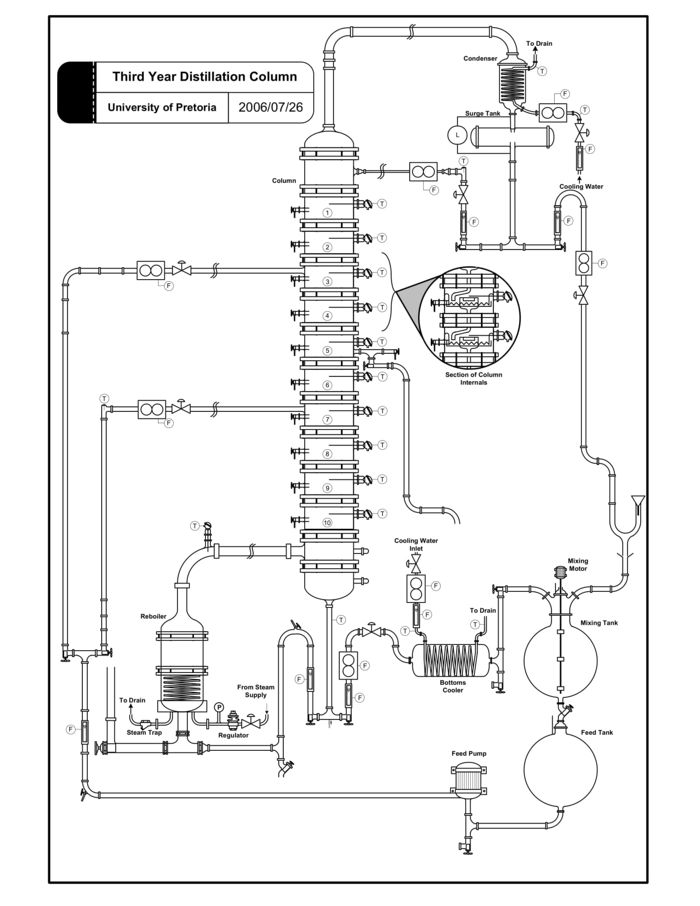

Description

The glass distillation column was a donation made by Exxon Mobil in 1978. It is a standard glass distillation column with the main function of distilling ethanol/water mixtures. The column has 10 stages, custom made to include sample points on each stage. The column makes use of donut trays for each stage. Each stage is fitted with an RDT (resistance temperature detector) temperature measurement device. Column instrumentation include various Coriolis mass flow meters and refractive index analyzers. Feed plate 3 and feed plate 6 can be used to feed to the column. This is a closed system with the top product and bottom product being recycled and added to the feed mixing tank.

Diagram

Control system

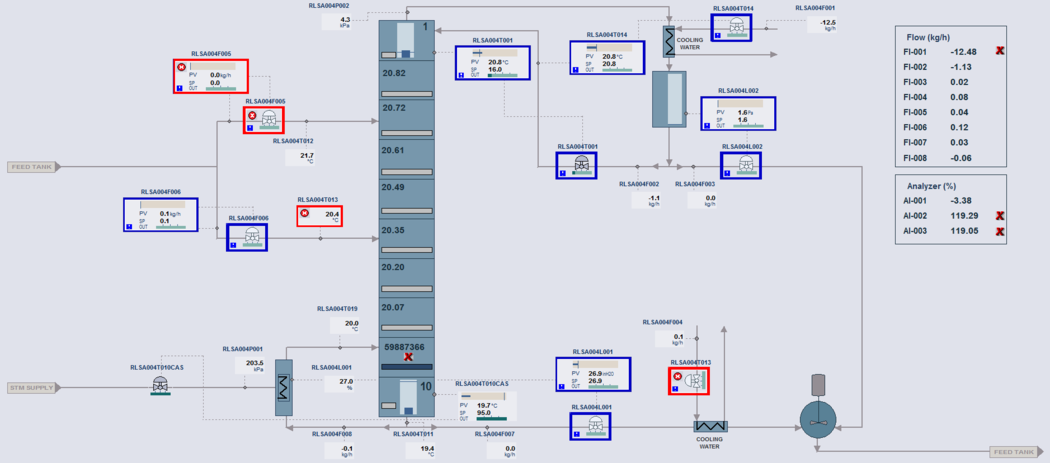

The column is currently controlled making use of the Emerson DeltaV v.14 software. The designed operator interface is shown below. Most of the control loops can be run either in manual or auto using the postulated base-layer control scheme. No APC is currently being employed for process control.

Operator interface

Contact persons

For help with the Emerson control system (Delta V) the contact person as of 2018-12 is:

Name: Daniela Straulino

Company: Avenge ACS

Tel: +27-11-249-6700

Cell: +27-82-407-8590

E-mail: Daniela.Straulino@avenggroup.com

For other general maintenance concerns and instrumentation problems the contact person is:

Name: Andre Joubert

Company: SASOL

Cell : +27-82-905-0090

E-mail : Andre.Joubert@sasol.com

Previous project documentation

Documentation on past projects that were done on the distillation column can be found here.

Help documentation

For help on the Delta V system and click here.