Difference between revisions of "T12 & T13 Ball On Cylinder Lubricity Evaluator (BOCLE) & Scuffing Load - Ball On Cylinder Lubricity Evaluator (SL-BOCLE)"

| Line 5: | Line 5: | ||

ball is forced against a rotating cylinder. The cylinder is partially immersed in a bath of the fuel to | ball is forced against a rotating cylinder. The cylinder is partially immersed in a bath of the fuel to | ||

allow the fuel to be constantly carried to the area of contact. | allow the fuel to be constantly carried to the area of contact. | ||

| − | |||

| − | |||

The BOCLE & SL-BOCLE machines operate on much the same principals. They are nearly identically | The BOCLE & SL-BOCLE machines operate on much the same principals. They are nearly identically | ||

| Line 13: | Line 11: | ||

2) The qualifying parameters and test methods (See ASTM link below).<br/> | 2) The qualifying parameters and test methods (See ASTM link below).<br/> | ||

3) The maximum load they can carry.<br/> | 3) The maximum load they can carry.<br/> | ||

| − | + | ||

| + | [[File:IMG 4440.JPG|400px|right|thumb|Ball,Ring & Bath]] | ||

| + | |||

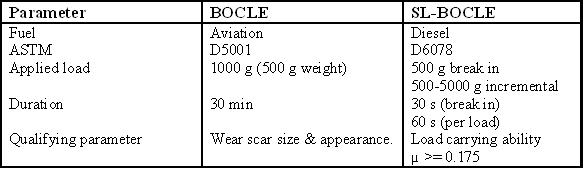

In this Table some basic differences are presented: | In this Table some basic differences are presented: | ||

Revision as of 07:50, 19 November 2012

Both the Ball On Cylinder Lybricity Evaluator (BOCLE) and the Scuffing Load - Ball On Cylinder Lubricity Evaluator work on the principle of testing the lubricity of a fuel/lubricant. A non-rotating ball is forced against a rotating cylinder. The cylinder is partially immersed in a bath of the fuel to allow the fuel to be constantly carried to the area of contact.

The BOCLE & SL-BOCLE machines operate on much the same principals. They are nearly identically

constructed. They differ in:

1) The types of fuels they typically test.

2) The qualifying parameters and test methods (See ASTM link below).

3) The maximum load they can carry.

In this Table some basic differences are presented:

The BOCLE is a wear test. A microscope and camera is used to quatify the size and record the appearance.

The SL-BOCLE is a load carrying capacity test. A series of loads are applied until a sudden

change in the friction coefficient is observed (higher than 0.175). This load then represents

some of the lubricity behaviour.

Note the suggested loading sequence in the operating manual.

Both units are operated via a simulink interfaces found on the PC next to the units (Univ PC nr: 766118).

Contents

Documentation

User Manual

A single user manual exists for both machines. click here

ASTM Standards

BOCLE (ASTM D5001)

click here

SL-BOCLE (ASTM D6078)

click here

MSDS of relevant Chemicals

Acetone

click here

Isooctane

click here

Isopropyl alcohol

click here

Reference fuels (A&B)

click here

Wiring diagrams

Overall wiring diagram Media:Example.ogg

Detailed Opto wiring diagram Media:Example.ogg

Piping diagram (Air flow)

click here

History of this Equipment

The equipment was recieved from Sasol in 2012 after being used there for a period of time. The equipment was conntected to the OPTO 22 network in 2012 by Jacques Langenhoven to allow data logging and control through the lab network and OPTO system.

Current/Previous projects

2012

Jacques Langenhoven, The commissioning of the BOCLE & SL-BOCLE in the Tribology lab

Media:Example.ogg