Difference between revisions of "Big distillation column"

(→Documentation) |

|||

| (39 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | [[Image:col_pic_1.png|right|200px]] | ||

==Description== | ==Description== | ||

| + | [[Image:col_pic_2.png|right|200px]] | ||

The glass distillation column was a donation made by Exxon Mobil in 1978. It is a standard glass distillation column with the main function of distilling ethanol/water mixtures. The column has 10 stages, custom made to include sample points on | The glass distillation column was a donation made by Exxon Mobil in 1978. It is a standard glass distillation column with the main function of distilling ethanol/water mixtures. The column has 10 stages, custom made to include sample points on | ||

| − | each stage. The column makes use of donut trays. Each stage is fitted with an RDT (resistance temperature detector) temperature | + | each stage. The column makes use of donut trays for each stage. Each stage is fitted with an RDT (resistance temperature detector) temperature measurement device. Column instrumentation include various Coriolis mass flow meters and refractive index analyzers. Feed plate 3 and feed plate 6 can be used to feed to the column. This is a closed system with the top product and bottom product being recycled and added to the feed mixing tank. |

| − | measurement device. Column instrumentation | + | |

| − | + | ||

| − | == | + | ==Control system== |

| + | The column is currently controlled making use of the Emerson DeltaV v.14 software. The designed operator interface is shown below. All the control loops can be run either in manual or auto using the selected base-layer control scheme. No APC is currently being employed for process control. The PID loops were tuned using InSight, a PID tuning tool in DeltaV | ||

| − | + | ==Operator interface== | |

| + | [[Image:8.PNG|center|1000px]] | ||

| − | + | ==Instrumentation== | |

| + | The column has 8 control valves, 8 Coriolis mass flow meters, 19 temperature transmitters, 4 pressure sensors and 3 composition analysers. This gives the column the necessary measurements to ensure control is possible. At the current time, FT-001 gives a negative flow reading and AI-002 does not shine a laser. This is the only known cases of instrumentation that is not working on the column. It is recommended that these problems be addressed. | ||

| + | ==Projects== | ||

| + | === 2018: Deon Pretorius, Greg Laycock === | ||

| + | '''Set-up''' The DeltaV software was updated from version to 9 and 14. This required the old hardware to be removed and new hardware to be installed. | ||

| − | + | '''Operator interface''' The original SASOL graphical user interface was removed and a new user interface was designed and implemented. | |

| − | + | '''Control valve response tuning''' The control valve responses to set-points were insufficient. The control valve responses were tuned to ensure smooth transition to set-point with no offset or hunting. | |

| − | + | '''Maintenance''' The following maintenance was completed on the system: | |

| + | * Substantial leak below reflux drum repaired | ||

| + | * Fouling in reflux line removed | ||

| + | * Some RDT wiring redone | ||

| + | * Some flow indicator wiring redone | ||

| + | * New regulator installed | ||

| + | * New steam trap installed | ||

| − | E-mail | + | '''Base-layer control''' Initial base-layer control implementation. A reasonable base-layer control scheme postulated and added to the operator interface. |

| + | === 2019: Johan de Bruin, Justin Phillips === | ||

| + | '''Base-layer control''' base-layer control was tuned using InSight (A tool included with DeltaV). The control throughout the column is now adequate and the system is stable | ||

| + | |||

| + | '''Operator interface (GUI)''' The GUI was updated with new information. The graphic elements were redrawn to give a better representation of the column. The cooling utilities temperatures were added to the GUI and dysfunctional elements were deleted. The alarms were also addressed to some extent. | ||

| + | |||

| + | '''Modeling''' | ||

| + | An Aspen model of the system with suggested tray efficiencies were set up and modeled. The fits yield quite an improvement to the McCabe-Thiele model that was used previously. | ||

| + | |||

| + | '''Maintenance''' The following maintenance was completed on the system: | ||

| + | * Substantial leak fixes | ||

| + | * Installation of bottoms cooler mounting | ||

| + | * Repair to bottoms cooler leak | ||

| + | * Fix faulty instrumentation | ||

| + | * Connection of reflux drum level sensor | ||

| + | * Install 2 new sampling points | ||

| + | ==Contact persons== | ||

| + | |||

| + | For help with the Emerson control system ([[Delta V]]) the contact person as of 2019-11 is: | ||

| + | |||

| + | '''Name''' Daniela Straulino | ||

| + | |||

| + | '''Company''' [http://www.aveng-acs.com/ Avenge ACS] | ||

| + | |||

| + | '''Tel''' +27-11-249-6700 | ||

| + | |||

| + | '''Cell''' +27-82-407-8590 | ||

| + | |||

| + | '''E-mail''' Daniela.Straulino@avenggroup.com | ||

For other general maintenance concerns and instrumentation problems the contact person is: | For other general maintenance concerns and instrumentation problems the contact person is: | ||

| − | Name | + | '''Name''' Jan Prinsloo |

| − | Company | + | '''Company''' [http://www.aveng-acs.com/ Avenge ACS] |

| − | Cell | + | '''Cell''' +27-83-230-4876 |

| − | E-mail | + | '''E-mail''' Jan.Prinsloo@aveng-acs.com |

| − | ==Documentation | + | ==Documentation== |

| − | Documentation on past projects that were done on the distillation column can be found | + | Documentation on past projects that were done on the distillation column can be found on [http://ragnarok.up.ac.za/Rigs/BigDistillationColumn/ Ragnarok] or on the [https://drive.google.com/drive/u/1/folders/15bBdoE_5CU_bxyOYWCvDMT7eXZ0dDvFD Google drive]. |

| − | ==Help | + | ==Help== |

| − | + | For help on the Delta V system click [http://www.chem.mtu.edu/chem_eng/current/new_courses/CM4120/2009/Getting%20Started.pdf here]. | |

| + | The [https://guardian.emerson.com/ Guardian services] are also available. A username and password can be obtained from Daniela. | ||

Latest revision as of 11:58, 25 November 2019

Contents

Description

The glass distillation column was a donation made by Exxon Mobil in 1978. It is a standard glass distillation column with the main function of distilling ethanol/water mixtures. The column has 10 stages, custom made to include sample points on each stage. The column makes use of donut trays for each stage. Each stage is fitted with an RDT (resistance temperature detector) temperature measurement device. Column instrumentation include various Coriolis mass flow meters and refractive index analyzers. Feed plate 3 and feed plate 6 can be used to feed to the column. This is a closed system with the top product and bottom product being recycled and added to the feed mixing tank.

Control system

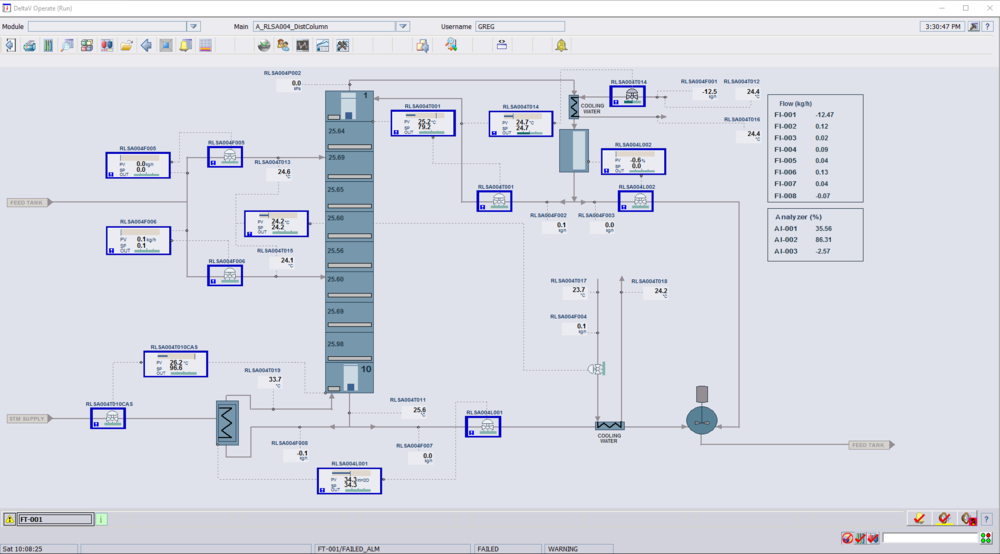

The column is currently controlled making use of the Emerson DeltaV v.14 software. The designed operator interface is shown below. All the control loops can be run either in manual or auto using the selected base-layer control scheme. No APC is currently being employed for process control. The PID loops were tuned using InSight, a PID tuning tool in DeltaV

Operator interface

Instrumentation

The column has 8 control valves, 8 Coriolis mass flow meters, 19 temperature transmitters, 4 pressure sensors and 3 composition analysers. This gives the column the necessary measurements to ensure control is possible. At the current time, FT-001 gives a negative flow reading and AI-002 does not shine a laser. This is the only known cases of instrumentation that is not working on the column. It is recommended that these problems be addressed.

Projects

2018: Deon Pretorius, Greg Laycock

Set-up The DeltaV software was updated from version to 9 and 14. This required the old hardware to be removed and new hardware to be installed.

Operator interface The original SASOL graphical user interface was removed and a new user interface was designed and implemented.

Control valve response tuning The control valve responses to set-points were insufficient. The control valve responses were tuned to ensure smooth transition to set-point with no offset or hunting.

Maintenance The following maintenance was completed on the system:

- Substantial leak below reflux drum repaired

- Fouling in reflux line removed

- Some RDT wiring redone

- Some flow indicator wiring redone

- New regulator installed

- New steam trap installed

Base-layer control Initial base-layer control implementation. A reasonable base-layer control scheme postulated and added to the operator interface.

2019: Johan de Bruin, Justin Phillips

Base-layer control base-layer control was tuned using InSight (A tool included with DeltaV). The control throughout the column is now adequate and the system is stable

Operator interface (GUI) The GUI was updated with new information. The graphic elements were redrawn to give a better representation of the column. The cooling utilities temperatures were added to the GUI and dysfunctional elements were deleted. The alarms were also addressed to some extent.

Modeling An Aspen model of the system with suggested tray efficiencies were set up and modeled. The fits yield quite an improvement to the McCabe-Thiele model that was used previously.

Maintenance The following maintenance was completed on the system:

- Substantial leak fixes

- Installation of bottoms cooler mounting

- Repair to bottoms cooler leak

- Fix faulty instrumentation

- Connection of reflux drum level sensor

- Install 2 new sampling points

Contact persons

For help with the Emerson control system (Delta V) the contact person as of 2019-11 is:

Name Daniela Straulino

Company Avenge ACS

Tel +27-11-249-6700

Cell +27-82-407-8590

E-mail Daniela.Straulino@avenggroup.com

For other general maintenance concerns and instrumentation problems the contact person is:

Name Jan Prinsloo

Company Avenge ACS

Cell +27-83-230-4876

E-mail Jan.Prinsloo@aveng-acs.com

Documentation

Documentation on past projects that were done on the distillation column can be found on Ragnarok or on the Google drive.

Help

For help on the Delta V system click here. The Guardian services are also available. A username and password can be obtained from Daniela.