Difference between revisions of "T11 Optimol SRV 4 Machine (New Machine)"

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

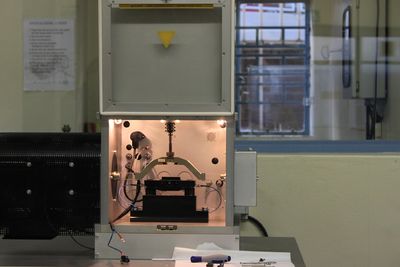

| − | [[File: | + | [[File:SRV2.JPG|400px|right|thumb|The SRV 4 Machine in the Tribology Lab]] |

| − | [[File: | + | [[File:IMG_5290.JPG|400px|right|thumb|The SRV 4 Machine Rig]] |

The Optimol SRV 4 apparatus (SRV is a german acronym for oscillation, friction and wear) is a multiple lubrication test machine. It is | The Optimol SRV 4 apparatus (SRV is a german acronym for oscillation, friction and wear) is a multiple lubrication test machine. It is | ||

Latest revision as of 16:17, 3 July 2013

The Optimol SRV 4 apparatus (SRV is a german acronym for oscillation, friction and wear) is a multiple lubrication test machine. It is versatile in the sense that most of the tests parameters are editable by means of the installed software. These parameters mainly include: load, stroke, temperature, load stepsize, machine cut-off values etc.

Basic tests include:

A constant load test (like the HFRR) An increasing load test where the load increases @ 50N/min to evaluate the Load Carrying Capacity (LCC). This test is also known as a film life test.

The machine traditionally tests the lubricating properties of oils and greases, but at the University of Pretoria it is used to test diesel lubricity together with the HFRR

There is no ASTM or ISO standard for testing diesel fuel with the SRV but the "in-house" test developed for testing diesel utilizes conditions that are closer to that of modern engines, when compared to the HFRR.

Contents

Current/Previous projects

2011-Vivian Moller (*Masters):

Fundamental study on diesel wear test.

Fundamental study on diesel load carrying capacity test.

Effect of lubricity additive concentration.

The role of oxygen.

2012-John Wittstock(CSC 411): Role of oxygen on SRV LCC.

2012/2013-Jacques Langenhoven(ISAF 2013): Study on lubricity additives.

2013-Ruan Nell(CSC 411): The role of oxygen on SRV LCC.

2013-Sipho : Solid lubricant disperssion for metal cutting fluids.

Documentation

User Manuals

The SRV Operation Manual can be found 4 Operating Manual.pdf

Test Procedure

The SRV Open Gear Lubricants Procedure

Download the SRV OGP Test Description

The SRV test procedure for open gear lubricants (SRV OGP Procedure) is intended as a screening test for the performance of open gear lubricants. A load test as well as a friction and wear test is performed at three temperatures, namely 25, 55 and 80°C. A ring is fitted around the top specimen and filled with grease, prior to the onset of the test, so as to ensure that the surfaces in contact are always replenished with lubricant and no starvation occurs, as might be the case when higher- consistency greases are tested without a ring.

SRV Diesel Test Procedure

The ball, disc, tweezers and other hardware and utensils are cleaned in the same manner as used for the HFRR. After the acetone wash, the specimens and hardware are left to air dry on a clean paper towel.

Once the disk is dry, it is wrapped in Teflon tape and the sample retaining ring is placed over the disc and secured into place. The ball is placed into the triangular chuck and the microscope used to ensure an undamaged surface is used for the test. The chuck is then secured onto the test rig and the disc and sample retaining ring also clamped into place. The discharge end of the fuel feed system is connected to the inlet of the sample retaining ring and a plastic tube is placed over the discharge end of the sample retaining ring to allow for overflow of fuel to go into a beaker set in place for this purpose.

The chamber was then closed. The sample is then allowed to cover the disc and then the feed rate is controlled at 1 drop every 3 seconds. The initial 50N load is applied and the test started. The test is automatically stopped when breakthrough occurrs, once a friction coefficient of 0.3 is exceeded.